Our

Products

Our

Products

|

|

We are a prominent manufacturer, supplier and exporter of highly efficient, high temperature cartridge heaters. These are manufactured using a nickel-chrome resistance wire which is swiftly wound around a Magnesium Oxide core to construct a cartridge heater. It is fitted into a stainless or Incoloy tube, placing the resistance wire close to the sheath. Inside the tube, the Magnesium Oxide core is centrally placed and the magnesium oxide powder filled on it. Nickel pins are passed through the middle of the core making touch with the resistance wire on both the sides. The external sheath gets an excellent heat transfer with the aid of a swaging operation. The heater is closed from one side with a welded metal end-disc and wire leads exit at the other side which is typically closed with a lava seal. The options of a variety of wire leads and lead protection are acquirable. Heaters Cartridge can be catered with internal thermocouples, mounting fittings and many other options. |

|

| Applications: | ||

|

|

|

|

|

|

||

|

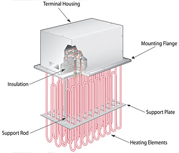

We design quality Flanged Immersion Heater which is used for heating gases and liquids in pressurized vessels and tanks. Flange Heater is one of the most widely used methods for heating liquids (such as water, oil, heat transfer fluid and corrosive solutions). It is integrated with flange, which is welded to tank wall in this heater. This heater is also called hairpin-bent tubular element which is brazed or welded into the flange. In case of Circulating Type Heaters, the flange is welded to a pipe. This type of Immersion Heater is acknowledged for its optimal performance in the heating of gases & liquids and generation of steam in the tanks and pressure vessels. There is a variety of sizes and electrical enclosures available for this Flange Heater. |

||

| Applications: | ||

|

|

|

|

|

|

||

|

|

The Cast In Heaters offered by us have an efficient liquid cooling function which is used to maintain suitable temperature of barrel, during the process of extrusion. Our Cast Steel Heater has various liquid cooling variations, terminations and styles. The Cast Iron Heater also has a stainless steel terminal box that offer a cost effective way to do away with vulnerability to live electrical terminals. To attain optimum amperage carrying capacity, positive electrical contact is required. This is ensured with 10-32 threads threaded post terminals that are safely fastened to the tubular heating element cold pin. The screw terminals are supported by ceramic insulators that are especially designed in the standard terminal. Bending or breaking of screw

terminals from rigorous mechanical work can occur. Hence to prevent

this, the tubular heater is recessed into the insulator. Incoloy tubes give best performance when exposed to their extensions, even under complex conditions. This is in comparison to the stainless steel tubing. We have also found that in Cast In Heaters, a tubing with 0.049-inch thick wall is important to preventing cracked cooling tubes, a condition which may occur because of linear thermal expansion.

|

|

| Applications: | ||

|

|

||

|

|

||

|

We design quality Flanged Immersion Heater which is used for heating gases and liquids in pressurized vessels and tanks. Flange Heater is one of the most widely used methods for heating liquids (such as water, oil, heat transfer fluid and corrosive solutions). It is integrated with flange, which is welded to tank wall in this heater. This heater is also called hairpin-bent tubular element which is brazed or welded into the flange. In case of Circulating Type Heaters, the flange is welded to a pipe. This type of Immersion Heater is acknowledged for its optimal performance in the heating of gases & liquids and generation of steam in the tanks and pressure vessels. There is a variety of sizes and electrical enclosures available for this Flange Heater. |

||

| Applications: | ||

|

|

||

|

|

||

|

|

We hold incomparable expertise in designing

comprehensive range of Hot Runner Heaters, Electric Hot Runner

Heater, etc. as per the exact client specifications or requirement.

As a well trusted manufacturer, supplier and exporter, it is our

prime responsibility to provide complete satisfaction to the

customers. Therefore, we assure our clients of impeccable product

quality, prompt services, ethical business policies and best market

rate. Our Hot Runner Heaters are designed in sync with the latest

engineering standards. Furthermore, the manufactured products are

tested by a team of vastly experienced quality inspectors. |

|

| Applications: | ||

|

|

||

|

|

||

|

|

Specially designed using rust resistant steel

sheath casing, VKE Band Heaters provide the best combination of high

emissivity, physical strength and good thermal conductivity to heat

cylindrical parts. Specially selected grade and thickness of mica

sheet is used inside it to isolate the windings which is made of

nickel chrome resistance ribbon wire to acquire the lowest internal

element temperature possible. It results in long lasting heater

life. The ribbon wire is wound evenly spaced on a preferred mica

strip to provide even heat distribution and to eliminate hot

spotting that can lead to unanticipated heater failure. Here, a low

thermal expansion alloy sheath is used for the outer sheath covering

the entire width of the Band Heater. |

|

| Applications: | ||

|

|

|

|

|

|

||

|

|

We are a trusted name when it comes to premium

quality Industrial Glass Heater. Ever since the inception, we are

engaged in manufacturing a comprehensive array of glass heaters that

are widely used in varied industrial segments for heating

applications. Counted among the leading manufacturers and suppliers,

we promise to offer unmatched product quality at best price as well

as within the committed time lines. All the products are

manufactured from highest grade raw materials, under expert

supervision. Further, we make sure to check the range of fabricated

Industrial Glass Heater, Flexible Fibre Glass Heater, etc. on few

well-defined parameters such as design, capacity, finishing, and

more. |

|

| Applications: | ||

|

|

||

|

|

||

|

|

Electric Duct Heater or Air Duct Heaters are used in various gas as well as air heating appliances. These are designed to be installed in existing ducting. Air Duct Heaters can be mounted in any direction. Electric Duct Heaters are used in air drying, dehumidification, autoclaves and lot more. The Duct heater is comprised of high quality Incoloy 800 elements mounted in a 3/8" thick flange using bulkhead fittings. It helps in easy replacement of the elements in the field. To keep the electrical wiring cooler, heat losses are minimized by high temperature isolation. |

|

| Applications: | ||

|

|

|

|

|

|

||

|

|

Used in Dies, Drying, Hot Plates, Molds, Ovens etc, our Strip Heater is offered in different shapes and sizes. The material of construction for Mica Strip Heaters include mica insulation (MI), stainless steel sheath (SSS) and Nickel-chrome resistance ribbon (Ni-Cr RR). As per basic design, Ni-Cr RR is winded around MI and then encapsulated in SSS. We have provided options for notches, holes and cut-outs in our Strip Heater, which has made it a flexible product. In the plastic processing applications, our Mica Strip Heaters are widely used. Also, they can provide heat to flat as well as curved surfaces. The heaters are equipped with wire lead options, multiple threaded terminals and terminal boxes that offer higher flexibility for field wiring. |

|

| Applications: | ||

|

|

|

|

|

|

||

|

|

An Infrared Heater is a body with a higher temperature which transfers energy to a body with a lower temperature through electromagnetic radiation. VKE Infrared Heater is manufactured by a firmly burnt-in heating coil to produce maximum output in form of heat energy. It can be operated in vacuum or atmosphere. It is used as a Heat Therapy Equipment, in Hot Stamping Machines, Shrink Packaging etc.. There is no risk of damage as it incorporates highly heatproof resistance wire. Resistance of the heaters is made to remain consistent over any temperature range . This provides a longer service life. The radiation efficiency of this heater is also very high. Portable Infrared Heater is easy to keep, acquires less space and cut in heating bills.

We offer Infrared Heater in 2 standard models: |

|

| Applications: | ||

|

|

||

|

|

||

|

|

We are a commendable manufacturer and supplier offering wide array of Flanged Heater. Designed and manufactured with precision to suit the varied client requirements, our products are hugely popular in the domestic as well as international marketplace. It is due to the hard work and dedication of our team that we are able to provide world class Flanged Circulation Heaters, Flanged Immersion Heaters, etc. to the customers. The immersion heaters find application in oil heating, water chemical tanks, electroplating industry, chemical plants, oil filtration plants, etc. We fabricate the entire range of heaters in sync with the industrial norms and latest engineering standards. |

|

| Excellent features of our Flanged Circulation Heaters and Flanged Immersion Heaters: | ||

|

|

||

|

|

||

|

|

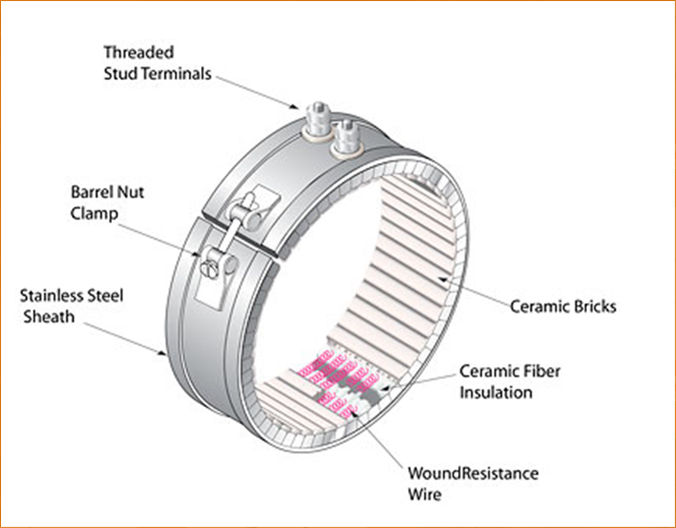

Longer heater life, high processing temperature capabilities and full flexibility for ease of installation characterize VKE Ceramic Band Heater. Ceramic Heater are space heaters that generate heat by passing electricity through heating wires embedded in ceramic plates. There are implicit thermal insulation to curb heat losses and for conservation of electrical energy. It is used in Blown Film Dies, Food and Candy Extruders, Drum Heating etc. A wound nickel chrome resistance wire is strung through high temperature ceramic bricks that sit on an insulation blanket of ceramic fiber insulation. It helps reducing heat losses by around 20% from un-insulated Ceramic Heater. Mounted on stainless steel casing with serrated edges, it provides strength and great flexibility such that the heater can be fully opened for security of installation. Heat is transmitted through conduction and radiation in Ceramic Band Heater. It can be customized in terms of sizes, clamping styles and multiple segment. |

|

| Applications: | ||

|

|

|

|

|

|

||

|

|

We are engaged in manufacturing an exhaustive range of Porcelain Heaters that offer large heated area to gases, semi solids or liquids to be heated (when inserted into thermo well). Being a quality oriented firm, we have constant focus on maintaining highest industry standards in our range of Porcelain Water Heater and Porcelain Gas Heater. Known to be a well reputed manufacturer, exporter and supplier, we procure raw materials from only reliable vendors of the market. Porcelain Heaters find application in water, gas, oil, foodstuff, anodizing and plating baths, alkaline solutions, etc. Furthermore, we specialize in customizing our offered range of products as per the specific requirements of the clients. Our gamut of Porcelain Water Heater and Porcelain Gas Heater has high resistance to fire, accurate designs and long service life. Some of the impeccable features that make our products hugely popular in the worldwide market segment are as follows : |

|

|

|

||

|

|

||

|

|

Used in many industries for heating and drying

requirements.

|

|||||||||||||

|

||||||||||||||

| We also manufacture Ovens as per Customers Requirement. | ||||||||||||||

|

|

||||||||||||||

|

|

Industrial Thermocouples are widely used for

process industry applications. We are offering large variety of

thermocouples to meet varied requirements of the buyers across India

as well as abroad. Our company is acknowledged as one of the

prominent manufacturers, exporters and suppliers of the industry.

Working in sync with the industry recommended guidelines, we are

offering a comprehensive range of Industrial Thermocouples and Base

Metal Thermocouples that are high on precision, strength, and

durability. We make sure to use only good quality materials for the

manufacturing of our range as well as incorporate latest

technologies time to time. |

|

|

|

||

|

|

||

|

|

Short Wave Ir Lamps consists of a quartz tube containing a coiled tungsten filament. The tube comprises of halogen gas and argon. Spacers/support rings are used to keep the filament in the center of the tube. Filament has less diameter than that of the quartz tube which prevents the it from coming in direct contact with the tube. Variations of internal reflectors and gold coating enhances and improves the basic Short Wave Ir Heating Lamps if external reflector assemblies are not used. They are available in a wide variety of voltages, wattage, end caps, either in clear or translucent quartz, and with or without a reflector. It is relevant for drying screen printing on T- Shirts, Fixing Toner in Copying Machines, Drying Glue on Paper, etc. Fast response (Rapid start) medium Wave Ir Lamps provide the fast start times of Short Wave Ir Lamps, with the wave length of medium wave lamps. The nominal working life of Ir Lamps is 5000 hours. They should not be contingent on severe vibrations and mechanical shocks. |

|

| Applications: | ||

|

ink, adhesives and lacquers |

drying inks |

|

|

|

||